The Magnesium Utilization Technology Research Team is developing a material utilization technology to make Magnesite, North Korea’s representative strategic metal resource, with high value-added, and to use it as a national flagship industry.

MAIN ACTIVITIES

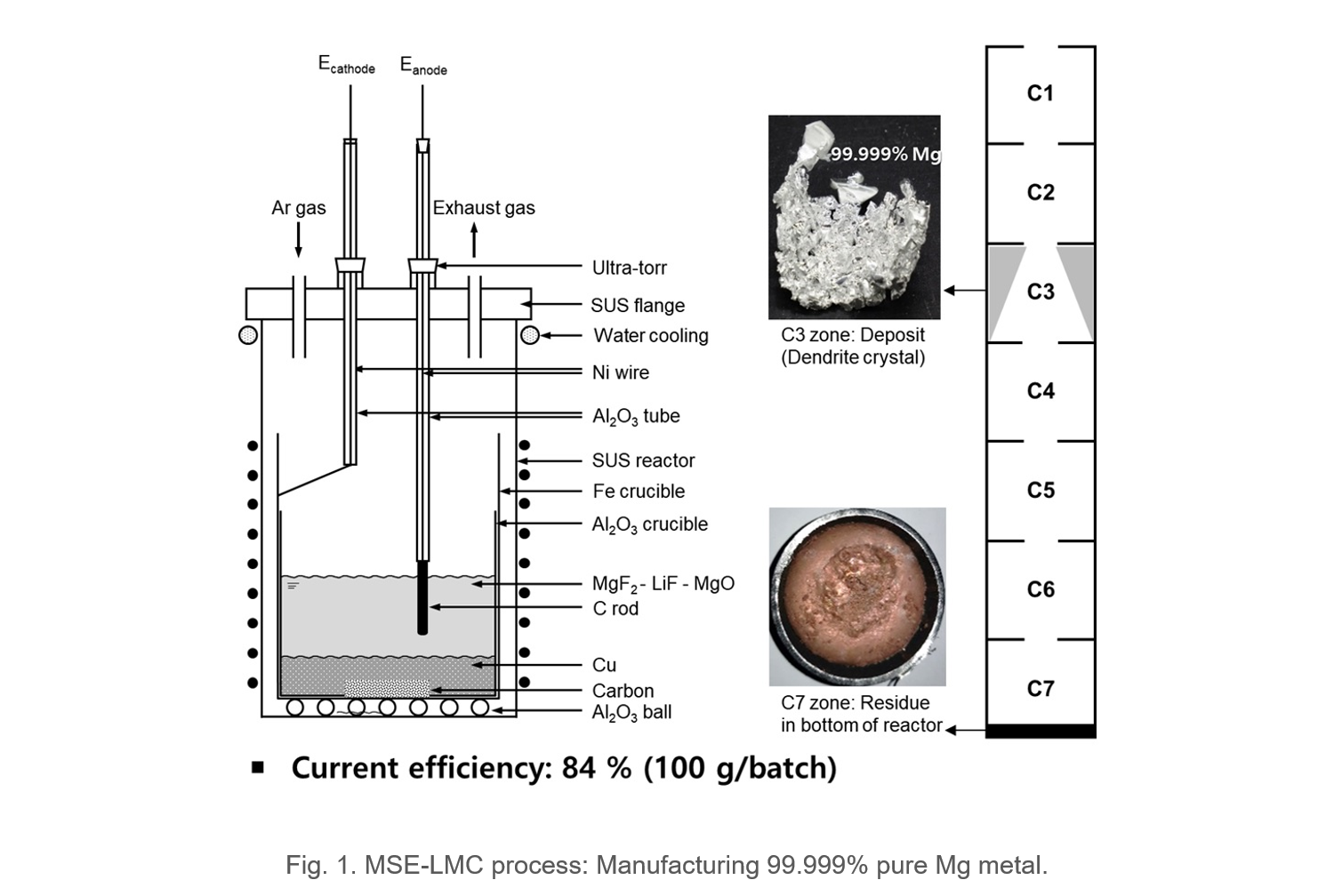

• Development of efficient and environmentally-sound scale-up process for production of high-purity magnesium metal using electrolysis of magnesium oxide

• Development of new magnesium alloys customized for Magnesite

• Development of pilot-plant scale manufacturing technology for high-strength magnesium alloy with low yield-asymmetry

• Development of manufacturing technology for new magnesium alloy sheets with excellent formability and corrosion resistance

MAIN RESULTS IN 2019

• Development of scale-up MSE-LMC (Molten Salt Electrolysis using Liquid Metal Cathode) process through production of Mg alloys by electrolysis of magnesium oxide using liquid-metal cathode and vacuum distillation of Mg alloys obtained for production of high-purity magnesium metal

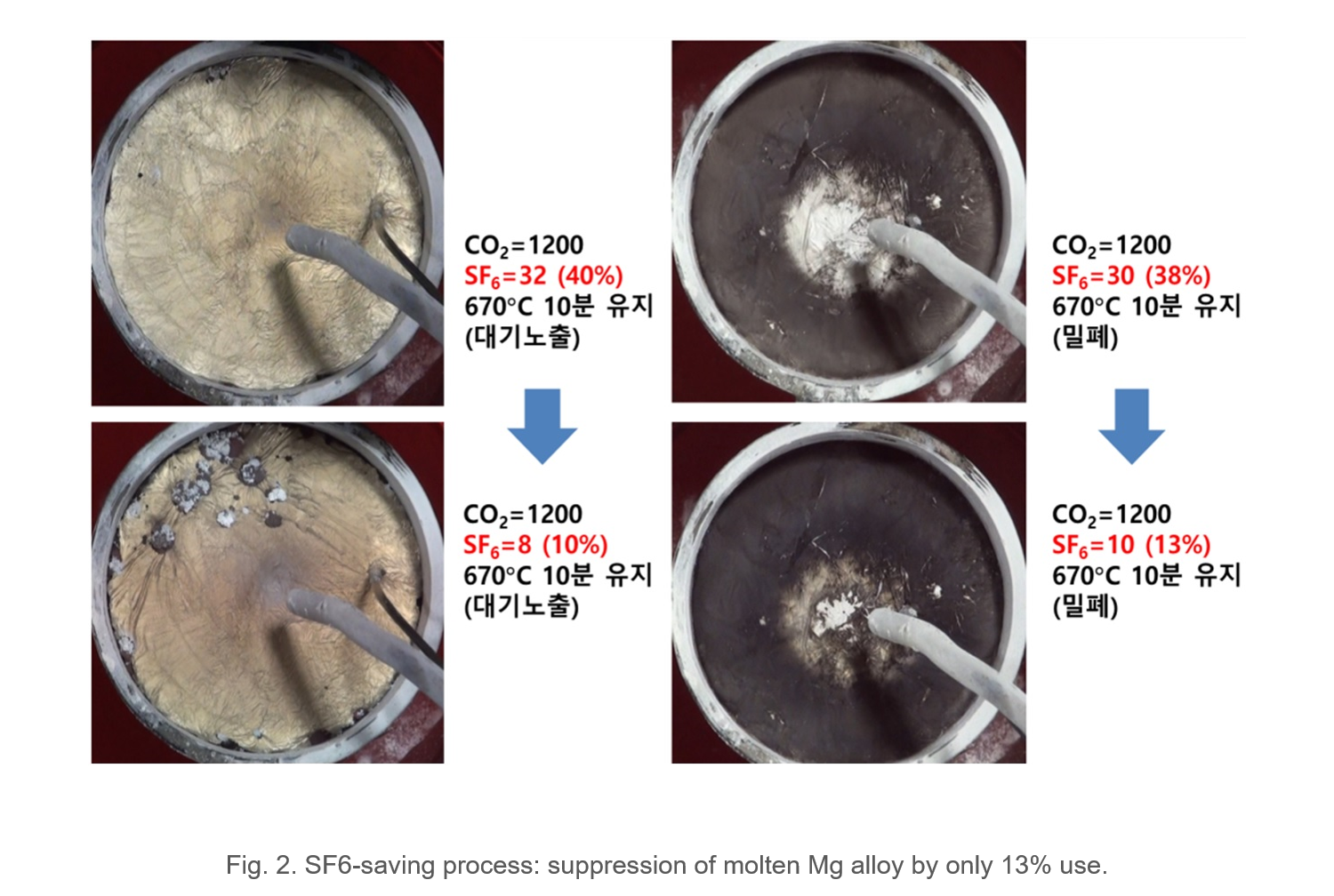

• Development of new magnesium alloys for SF6-saving (~80%) casting processes and high-strength precipitation hardened magnesium alloys suitable for mass-production extrusion processes

• Development of manufacturing technology for magnesium alloy extruded materials that can be applied to advanced transportation vehicles such as automobiles, railways, and aircraft through close cooperation with domestic and overseas research institutes and manufacturers (yield strength: 245 MPa, yield asymmetry: 0.93)

• Development of magnesium alloy sheets and pilot plant scale-up technology leading to the world’s highest level of multi-performance

Contact: Young Min Kim (youngmin@kigam.re.kr)