- Nameadmin

- Date2014/12/15 00:00

- Hit1,015

Sustainable Innovation Recycling Technologies for Waste Paper Pulp

In-situ processing with Precipitated Calcium Carbonate:

The World’s First Technology and First Pilot Plant Demonstration

Korea Institute of Geoscience and Mineral Resources (hereinafter KIGAM, President Dr. Kyu Han Kim), Ministry of Trade, Industry and Energy (hereinafter MOTIE), and Korea Institute of Technology Evaluation and Planning (hereinafter KETEP) are planning to hold a ceremony of the successful Research and Development research results on December 10, celebrating the commercialization for convergence technology between cement industry and coal power plants.

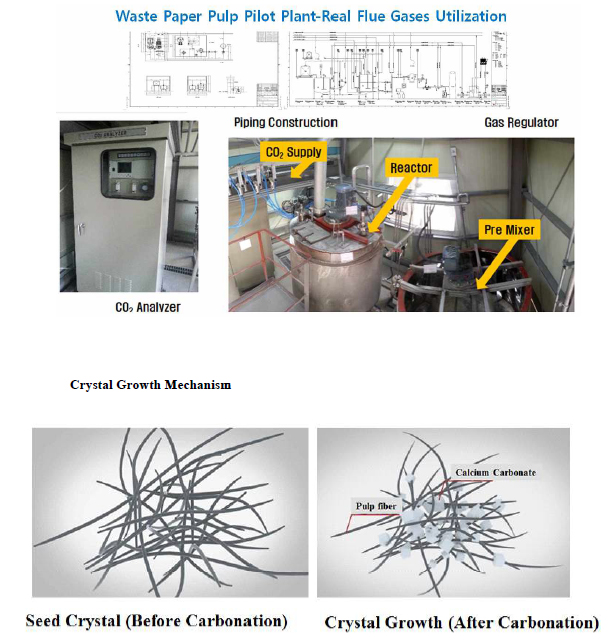

KIGAM will announce on the ceremony that it successfully finished the world's first pilot plant demonstration of paper convergence technology with Hansol Paper Co., Ltd. And Hanil Cement Co., Ltd through Industry-University collaboration (capacity 3m3/day).

Old news paper (ONP) and old corrugated containers (OCC) are recycled by In-situ process with precipitated calcium carbonate (PCC) which is from limestone. The in-situ PCC technology had patented and has been converged in paper recycling industries as well as limestone paper industry.

Paper is a source of green energy which is an increasingly important part of the solution to climate change. Recent studies show 30 to 40 percent of municipal solid waste is paper and paper products, and 50% of office waste that goes to landfills is also paper. Paper waste has significant embedded greenhouse gas (GHG) emissions resulting from other phases of paper’s life cycle. Wasted paper alone constitutes 48 percent of the greenhouse gases emitted during the production of products that wind up in a ton of 'municipal waste' sent to landfill. Our basic vision and approach are based on Cost action E48, which is an ideal paper project in Europe. One of our visions is reducing climate change greenhouse gas (GHG) emissions by recycling the waste papers. For every ton of recovered paper that is converted into new recycled paperboard for packaging and other end uses, 3.6 million metric tons of CO2emissions are eliminated. Another issue is cost of the pulp. The cost of fiber is a key value driver for both recycled and virgin producers of papers. Currently the 1 ton of virgin pulp price is approximately 665$. Limited sources of pulp in South Korea makes recycled paper rate much higher than developed countries.

One of the best solutions proposed is in-situ process (precipitated calcium carbonate), an innovative paper loading method which could lead to higher filler retention and a better relationship between the optical and strength characteristics. It enhances both the optical and strength properties of paper on the benefits of the in-situ loading method, along with a very high retention yield. It is also found out that the optical properties of in-situ loaded paper are consistently higher and more innovative than conventional loading. In addition, considering the rate of waste paper that is converted into a new recycled printing paper is only 10%, which means we can only take quantitative approach, this technology can be viewed as an innovation.

In Korea, this paper In-situ technology is more economic and similar to NICE 3 paper project in Europe. The highlights of this technology include 1) Raw Material, cost savings: use of recycled old news paper (ONP) pulp and old corrugated containers (OCC) pulp 2) Energy Savings: 45 percent of the energy saving, improved dewatering & not required drying process 3) product characteristics improvement: for ONP, ash content 27%, brightness, 70%, and for OCC, ash content 20%, brightness 56%, 4) Strength: increased strength of finished paper. Since a 1% increase in ash content is highly difficult, a 10% increase when real production through in-situ technology can be seen as world-class results.

However, it was found out that the properties of IGT strength and opacity remain lower, so they will solve this problem by on-site process and commercialize.

This technology has wide benefits including CO2emission reductions, CO2 utilization, cost competitiveness, simple process and economic. In Korea, especially the degree of utilization of writing paper, printing paper recovered is higher than other countries. This core technology was introduced and innovated by Dr Ahn Ji Whan, who is working as a Principal Researcher in Korea Institute of Geoscience and Mineral Resources and Director of Resources, Environment and Materials R&D Center, KIGAM. Dr. Ahn Ji Whan has 20 years’ experience in recycling of waste materials, and won the President Prize of Science Patriot Award for her innovation in real gas utlization research and CCUS. She has cooperative collaboration research with Hansol Paper Co., Ltd. and Hanil Cement Co., Ltd. Recently, Hansol Paper Co., Ltd. adopted Dr. Ahn Ji Whan’s technology and demonstrated it successfully. For this process, they utilized real flue gases including 8 to 10% concentrated CO2 gas. This is the best way to capture CO2 gas for sequestration and utilization(CCUS) and more beneficial to climate change by reducing the CO2 emissions.

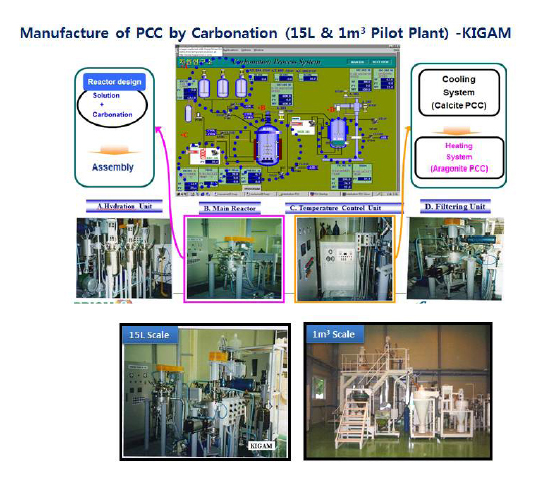

Dr. Ahn Ji Whan established precipitated calcium carbonate pilot plant in 2002. This synthesized pcc is currently used in the study of recycled paper making (In-situ process). ISoutheast Asian countries such as Vietnam and the Philippines have interest in applying our technology for the development of their own resources.

Dr Ahn Ji Whan has developed a convergence technology that could help realize President Park's vision for “creative economy”. Dr Ahn is planning to export this technology to the World. Dr Ahn will start Creative Economic Action Plan from Daejeon City and Danyang City on the small scale and then expand its scope into the whole Chung cheongbuk-do Province. In-Situ PCC, a convergence technology is a best model for CCS (Carbon capture and storage) and CCUS((Carbon Capture Utilization and Storage) to cope with climate change, and can produce high-quality paper by recycling waste paper, which in turn leads to solving social problem and promoting creative industry, a role model for “creative economy”.