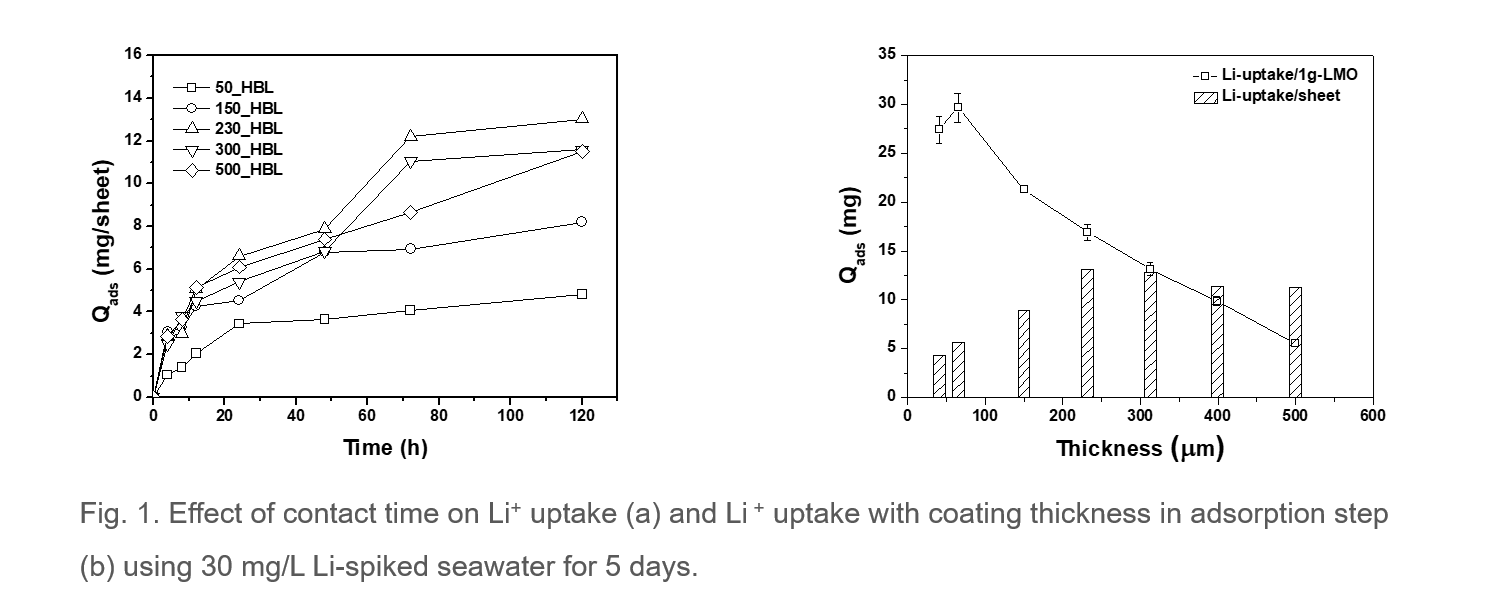

The industrial demand for lithium, especially in batteries, is expected to be high in the near future. The recovery of lithium dissolved in seawater has attracted considerable attention since seawater has a huge reserve amount (2.5 x 1014 kg of lithium) of lithium compared to conventional reserves such as continental brines and mines. The use of lithium-selective adsorbents, such as spinel-type lithium manganese oxides (LMOs), show potential for recovery of lithium from seawater. This approach for the recovery of lithium from seawater was evaluated using a new composite of LMO and epoxy-silica hybrid binder (HB) prepared by sol-gel method. The adsorbed Li+ amount (mg/sheet) of delithiated LMO/HB (HMO/HB) composite increased and maintained an almost constant level when coating thickness was higher than 230 μm (Fig. 1). The coating thickness of the composite played a key role in the adsorption process, which could be attributed to the diffusion limitation with coating thickness of LMO/HB composite. Thus, an adequate level of coating thickness is required for the practical recovery of Li+ from aqueous solution without the unnecessary use of adsorbent powder in the adsorption process.

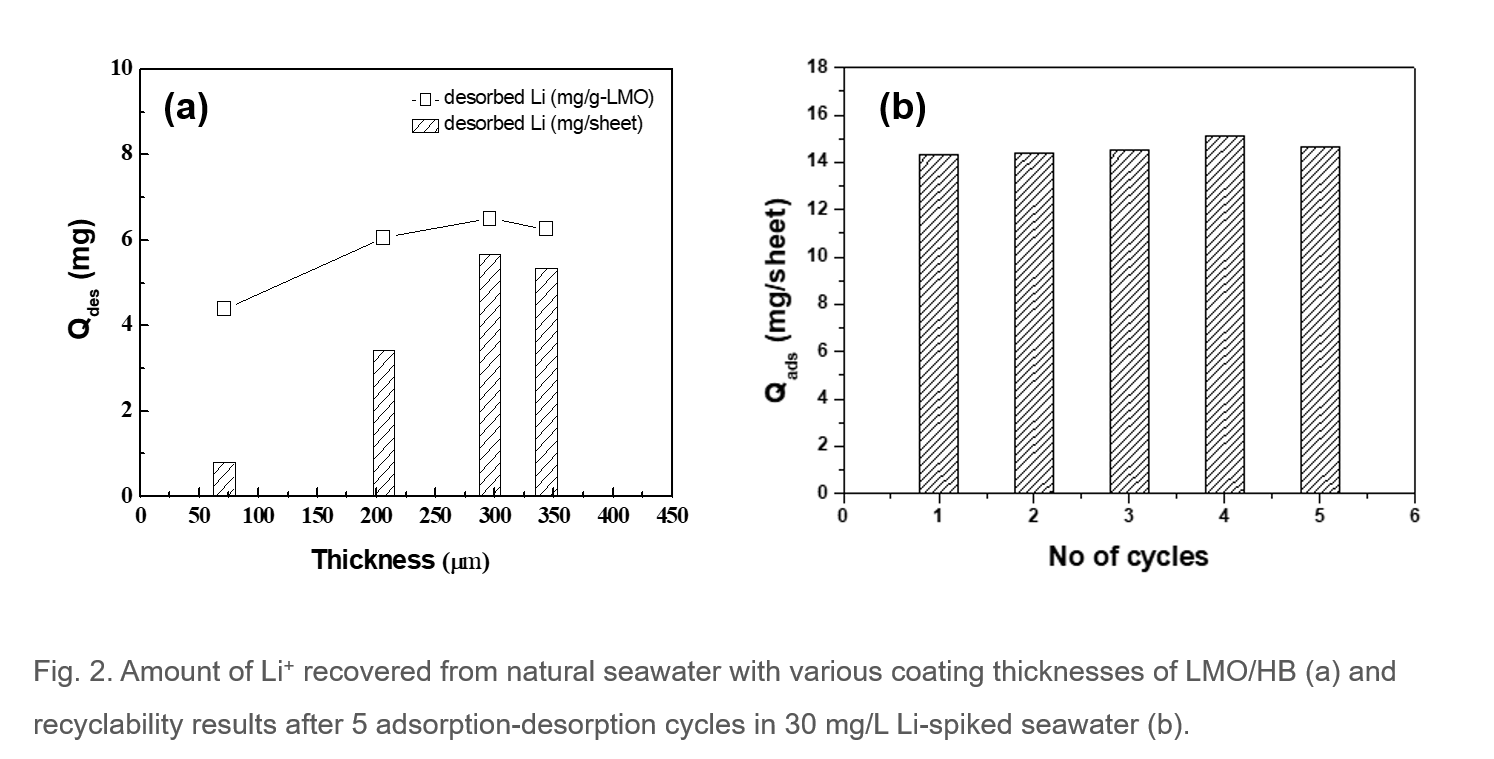

HMO/HB composite with various coating thicknesses was applied for Li+ recovery from natural seawater. Seawater flowed into a continuous fixed bed reactor equipped with HMO/HB composite at a flow rate of 5 L/min for 7 days and Li+ was recovered; Li+ adsorbed HMO/HB composite was immersed and stirred in 0.3M HCl solution for 24 h (identical to conditions used to prepare HMO/HB composite, sample/2L HCl sol.). The amount of recovered Li+ (mg/sheet) increased with increasing coating thickness and maintained an almost constant value after the coating thickness had increased up to approximately 300 μm, which resulted in a maximum Li+ uptake value of about 6.5 mg/g (67% in comparison to that by powder HMO) at a coating thickness of 300 μm (Fig. 2a). The durability of the HMO/HB composite (300_HBL) was examined by repeating a cycle of consecutive adsorption in 30 mg/L Li-spiked seawater and desorption in 0.3 M HCl five times. The amounts of recovered Li+ (mg/sheet) were maintained at almost identical levels during the five repeated tests (Fig 2b). The results show that powder LMO adsorbent can be practically applicable to seawater, forming a composite that is simply coated on PVC plate using epoxy-silica hybrid binder (HB) prepared by sol-gel method. This approach can be a potential candidate for practical application of adsorbent powders in the recovery process of lithium from seawater.

Contact: Taegong Ryu (tgryu@kigam.re.kr)