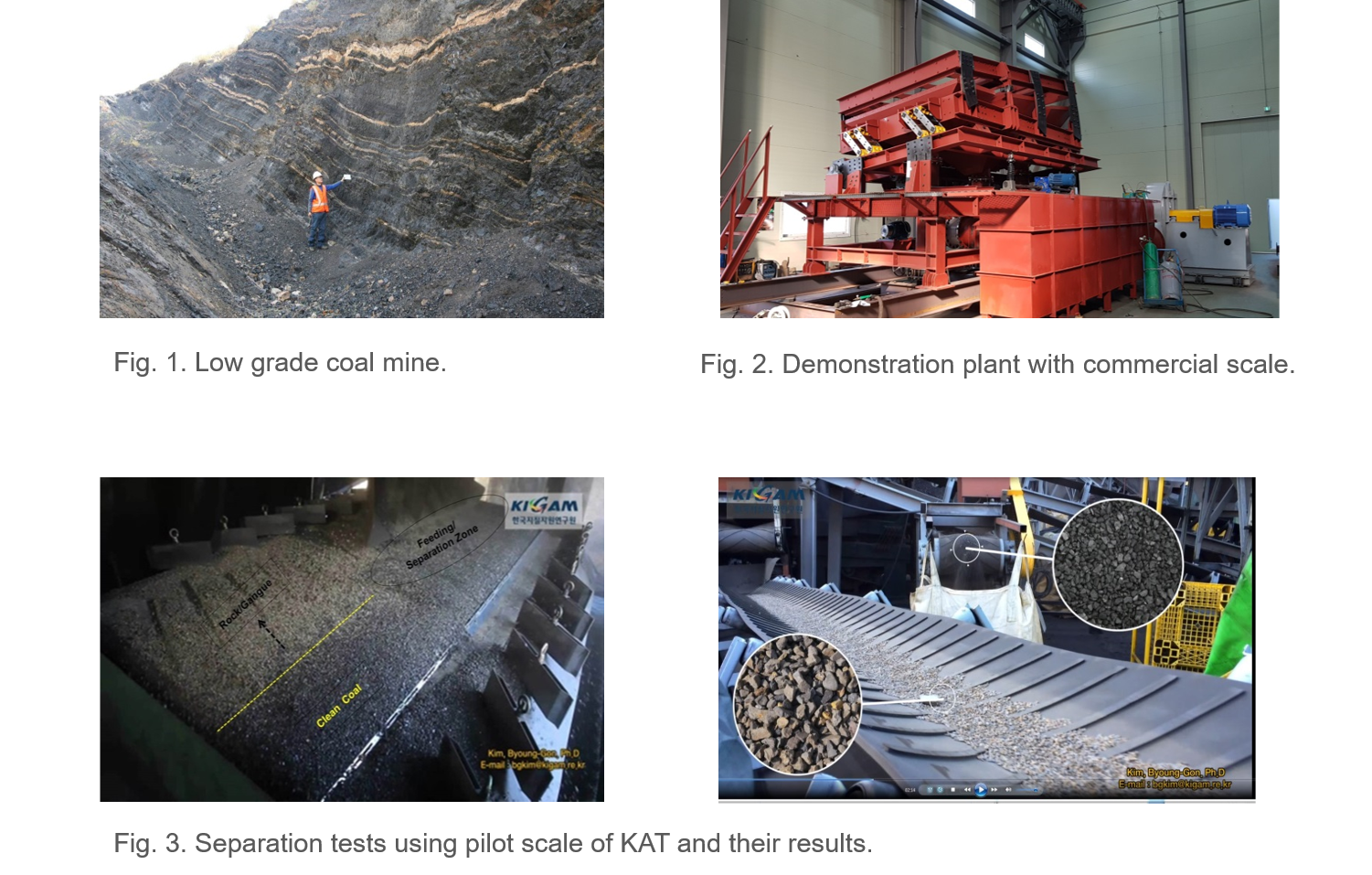

Low grade coal is not widely used because of the limits to coal preparation technologies, environmental issues, and economic feasibility. Most coal mines are located in places where water is not sufficient, or in remote areas; as such, a dry coal preparation process is essential. The Mineral Processing Department of KIGAM developed the KAT Process, an ecofriendly efficient dry coal preparation technology that features simple processes and ensures high economic efficiency. The KAT Process implements in-situ preparation through a simple process to save transportation costs and address environmental issues, thus addressing the greatest challenges in the conventional wet processes. Because the KAT Process broadens the size limitation in preparing coal of which granularity is smaller than 10 mm, and improves the quality of products dramatically, this process is ideal for coal mines as a main coal preparation process.

The separation efficiency of conventional air-fluidized layer decks is generally affected by particle size and size distribution, and quite bad for particles smaller than 20 mm. The KAT Process also employs an air-fluidized layer deck concept, but is designed to achieve a good efficiency even for particles smaller than 20 mm. Several test results reveal it can process coal particles as small as 1 mm quite efficiently.

The eco-friendly and economical KAT Process has attracted a lot of attention of Korean and overseas coal mine developers. This technology was already transferred to “KAT Co., Ltd.” for commercialization. And, overseas coal mining companies connected with global mining companies in Asia, including in Mongolia, Kazakhstan, Indonesia, Myanmar, Vietnam, and India, are also interested in the KAT Process. These interests show that this technology is competitive in terms of originality and applicability. “KAT Co., Ltd.” Is moving forward with demonstration project operation at commercial scale at coal basins in Korea and Mongolia.

Contact: Byoung-Gon Kim (bgkim@kigam.re.kr)